Recipe development

Recipe development based on predictive modelling

Sensory product attributes such as taste, smell, appearance and consistency are decisive for the success of a product. Each food producer has their own preferences and often their own signature: the decisions made during the development process of a recipe determine the product’s ultimate sensory properties.

This is why we closely collaborate with our clients when developing recipes: our clients decide on the ingredients to be processed, and – based on predictive modelling – we continue to create the preservation that best suits our client’s requirements for the product.

Sensory evaluation

While during its shelf life a product may still be according to standards microbiologically; odour, colour or taste abnormalities may occur. Smartfood R&D therefore offers the opportunity to combine accelerated shelf-life tests with sensory evaluation.

By assessing the appearance, smell, taste and texture of a product, any sensory abnormalities come to light more quickly. These abnormalities can often be remedied through a minor adjustment in the recipe or production process.

Friday morning urgent matter: a company with acute shelf-life issues that must be resolved before Monday’s production. By providing an adjusted recipe, we made every effort to get the company back on track that very same afternoon. The best compliment we have ever received was the following: ‘I have been getting far more and better sleep since we started collaborating with smartfood R&D'.

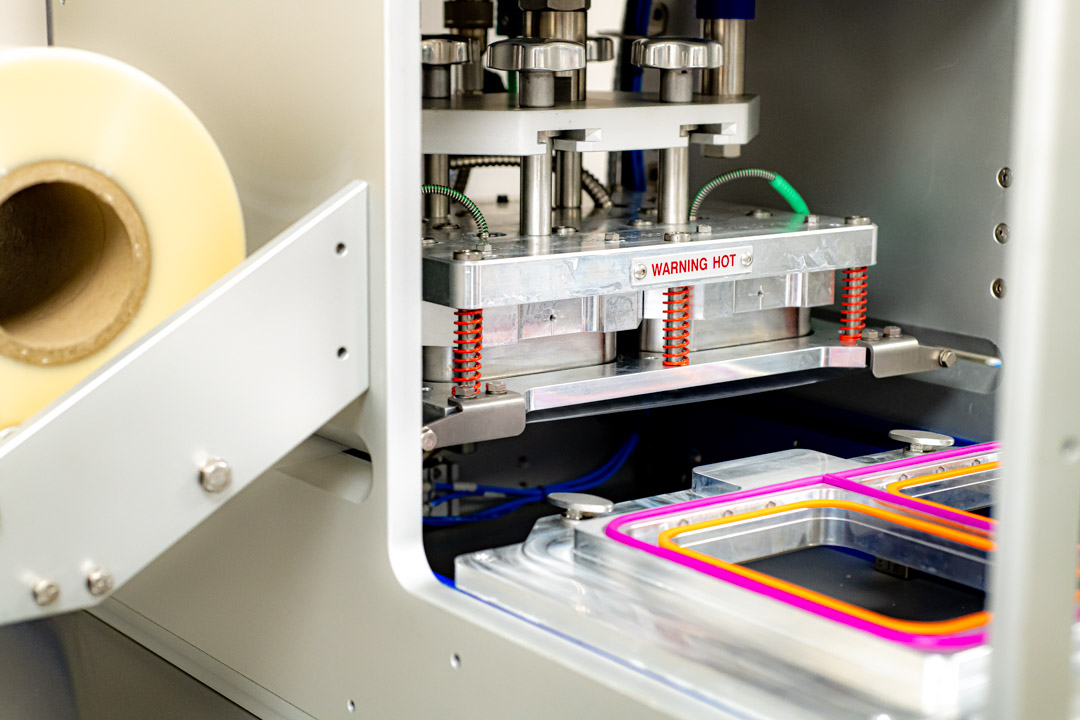

MAP pilot plant and vacuum packaging

Packaging plays an important role in food shelf life. Fresh products such as meat, fish, fruit and vegetables and ready-to-eat meals are often packaged under MAP (Modified Atmosphere Packaging) or vacuum. This is also referred to as gas packaging.

The composition of gas mixtures in the packaging affects the physico-chemical, enzymatic and microbiological reactions in the product and therefore their product shelf life.

Smartfood R&D has a packaging pilot plant where products can be packaged under a protective atmosphere or vacuum. This allows us to perfectly copy the MAP conditions in our clients’ final products on a laboratory scale.

By carrying out our shelf-life tests, we can measure the effect of adapting or breaking MAP conditions on the shelf life of final products, for instance.

View our other services

Accelerated shelf-life testing

Microbiological, physico-chemical and sensory shelf-life testing accelerated by a factor of up to 10.

Predictive modelling

Predictive microbiology is the initial step in substantiating the shelf life of your product.

Challenge tests

Challenge tests using pathogens and non-pathogenic micro-organisms for any product and process.

Industrial microbiology

Custom precision microbiology carried out in-house for each industrial production process.

Process Validation

Validation of processes for the effective control of microbiological risks.